Conceptual and detail engineering development is fundamental in structural and paillettering projects, key areas in industries such as construction, manufacturing and mining.

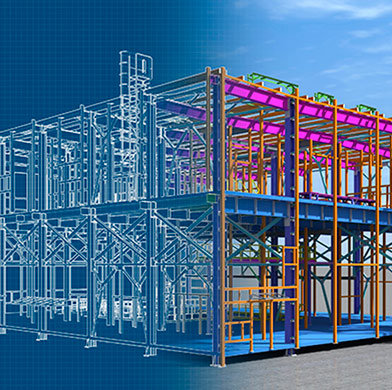

Traditionally, these projects were carried out using manual design techniques or 2D CAD. However, with the adoption of advanced technologies such as 3D scanning and Information Modeling for Construction (BIM), a revolution has emerged in the way these engineering developments are developed. These tools allow for greater accuracy and efficiency, from the conceptual phase to the detailed phase of projects, improving planning, execution and quality control of the structures and systems of the pailería.

3D Scanning: Precision and efficiency in conceptual and detailed design

3D scanning has transformed data capture processes into engineering projects. This technology allows for the creation of precise three-dimensional models of existing structures or environments, capturing all details quickly and accurately. For structural and paillettering projects, 3D scanning helps to generate an accurate representation of the components, which is key to developing precise conceptual engineering. It also facilitates the creation of detailed drawings for the manufacture and assembly of pailletters and complex structures.

In the conceptual phase, 3D scanning allows a clear view of the real environment, helping engineers identify potential problems or limitations early on in the project. This saves time and reduces costs, as errors and rework are minimized during construction. In addition, the integration of 3D scanning data with design software such as CAD or BIM systems allows a smooth transition between conceptualization and detailed design.

In the detailed phase, 3D scanning is especially useful for renovation or upgrade projects of existing structures where accurate information about current conditions is essential. By generating an updated three-dimensional model, engineers can develop detailed solutions that fit exactly to the real conditions, avoiding problems such as incompatibilities or interference during installation of pailletters or structural components.

BIM: The future of structural and pailletteing engineering

The adoption of Information Modeling for Construction (BIM) represents a significant evolution in the way engineering projects are managed. BIM goes beyond three-dimensional models, integrating detailed information on each component of the project, from technical data to schedules and costs. This ability to integrate multiple sources of information into a single centralized model is key to improving collaboration and decision-making in structures and pailería projects.

One of the biggest benefits of BIM in these projects is its ability to manage complexity. Pailletting and structural projects often involve the coordination of multiple engineering disciplines, such as mechanical, civil, electrical and more. Using a BIM model facilitates coordination between these teams, allowing them to work on a single source of truth. This reduces errors and ensures that all equipment is aligned with project specifications.

In addition, BIM allows for simulations and analysis before construction begins. For example, interference studies can be conducted to ensure that the components of the pageantry and structures do not overlap or interfere with other systems such as ventilation or air conditioning, which are also part of the project. This type of analysis is essential in industrial environments where space optimization and installation accuracy are crucial to ensure the stability and efficiency of operation, The same applies to industries handling raw materials or high-tech installations.

Advantages of integrating 3D scanning and BIM into projects

The combination of 3D scanning and BIM offers a clear competitive advantage for companies that want to carry out structural engineering and paillettering projects with the highest quality standards. By using these technologies, engineers can detect potential errors early in the project, make changes in real time and ensure that designed solutions fit perfectly into the real environment. They also improve project control, reduce costs and lead times, and increase safety in the construction process.

Ultimately, integrating these technologies into structures and pailletters not only improves technical performance but also increases the long-term sustainability and performance of facilities. As companies adopt BIM and 3D scanning, they are better prepared to meet the challenges of the future and meet the increasingly demanding requirements of the global market.

Adopting these technologies is not an option, but a necessity to maintain competitiveness and ensure quality in the development of modern industrial projects, especially in areas where system stability and installation accuracy, In the case of air conditioning or industrial ventilation, it is critical to its operation.